Researchers from the Institute of Technical Physics and Materials Science of the HUN-REN Centre for Energy Research (HUN-REN EK-CER) have developed methods based on optical and electrochemical sensors applicable in a microscopic environment, in collaboration with Aedus Space Ltd. and the Dutch company Micronit B.V. under the umbrella of the Moore4Medical ECSEL project. The new technology facilitates the direct mapping of the chemical environment and metabolism of cell cultures established in microfluidic Organ-on-Chip systems, thereby aiding in understanding the mechanisms of diseases and therapies. The results can significantly contribute to the acceleration of drug active ingredient testing and the replacement of animal experiments.

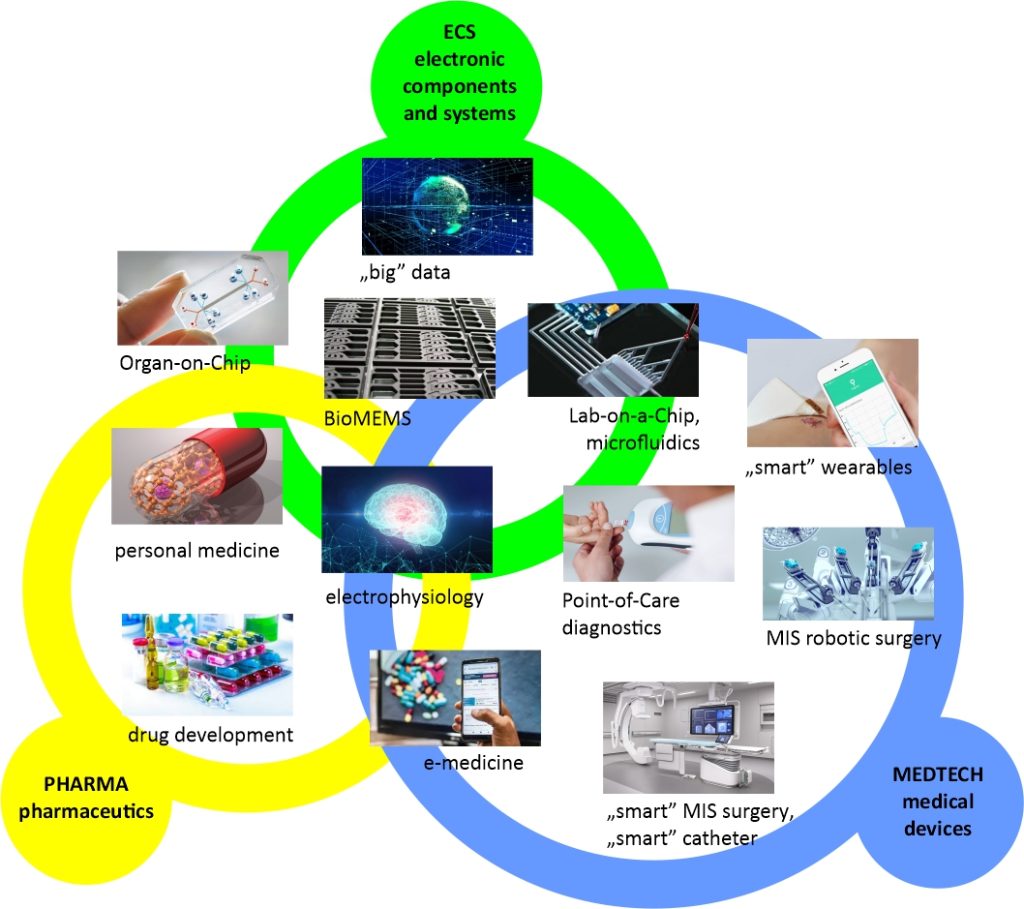

Nowadays, the boundaries between medicine, pharmacology, and electronics are becoming increasingly blurred. Innovative technologies developing at the intersection of these fields represent a significant advancement for both the industry and society towards a better functioning, more efficient, and affordable healthcare system. The application of micro- and nano-electromechanical (MEMS, NEMS) systems allows for the miniaturization of analytical systems, as well as the integration of various sensing, reading, intervention, and sample preparation functions. These highly sensitive, multifunctional yet compact-sized smart devices extend the possibilities of the medical technology and pharmacology industries, accelerate diagnostic decision-making, and expedite drug active ingredient testing.

The pharmaceutical industry focuses on the research, development, and testing of chemical and biological active ingredients, which are currently validated by parallel in vitro biological analyses or by extremely costly in vivo clinical trials. As alternatives to these, Organ-on-Chip devices have emerged, which, by replicating the foundational cultures of human organs and mimicking their fundamental functions, are capable of maintaining human cells in microfluidic systems in a controlled manner and continuously monitoring them with sensors. These devices can offer a better representative model for drug testing than cultured cell lines or animal experiments.

Even before the COVID-19 pandemic, the Moore4Medical project was organized with the collaboration of 68 participants from 12 countries. Led by Philips Research, one of the main goals of this international consortium was to create a complex standardized tool that could significantly accelerate the development and medical application of drugs. The pandemic definitively amplified this need and hastened developments in this direction.

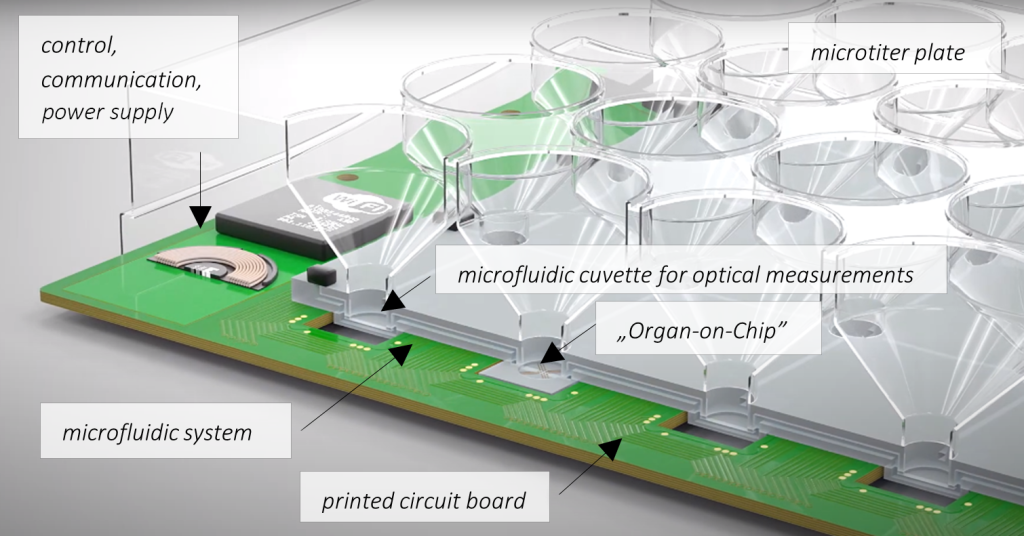

Developed within the Moore4Medical project, the advanced tissue culture plate prototype (smart multiwell plate platform, SMWP) combines microfluidic and electronic infrastructure to integrate the specialized Organ-on-Chip devices in a system that can be used in a standard manner by both the biotechnology and pharmaceutical industries.

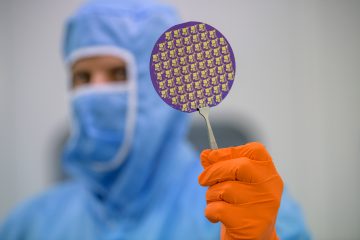

Aedus Space Ltd. participated in the development of industrial manufacturing technology for the microfluidic system that includes Organ-on-Chip devices, adapting high-precision laser welding solutions. In the HUN-REN EK-CER Microsystems Laboratory, optical and electrochemical sensors were developed and implemented, which allow for continuous monitoring of the chemical environment of cell cultures and the metabolism of the cells, and are compatible and can be integrated with the microfluidic systems.

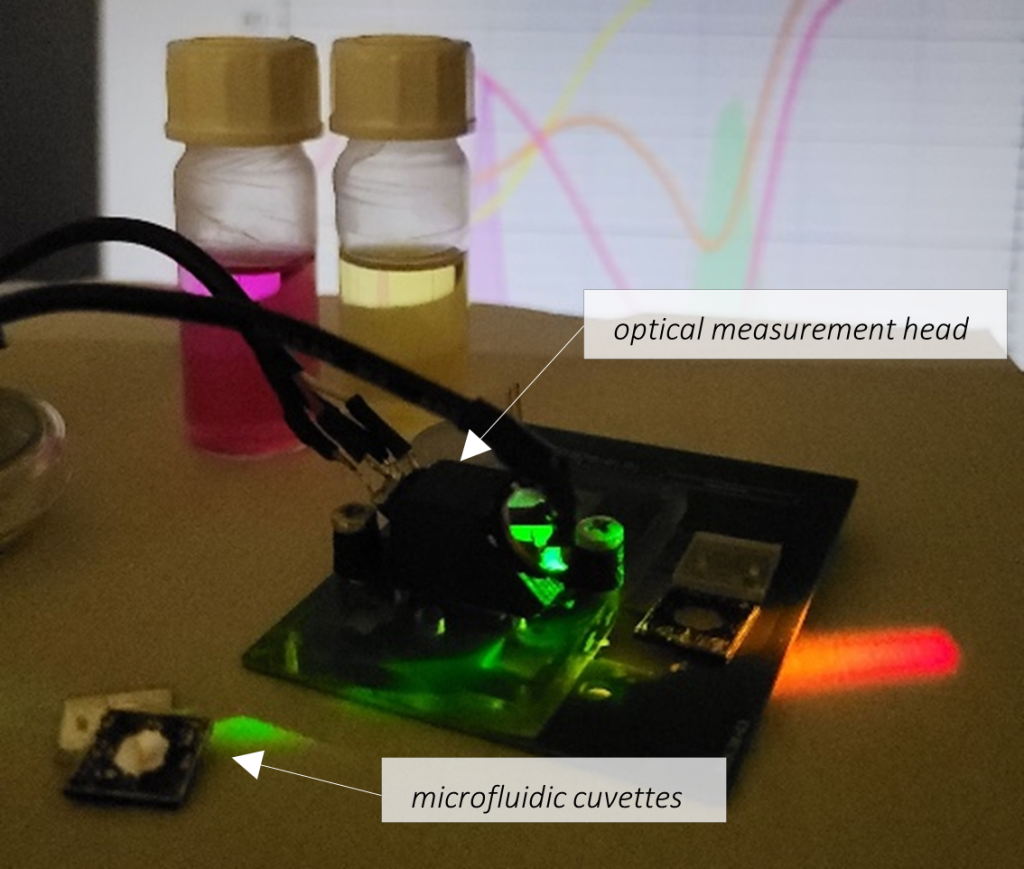

The prototype of the optical measurement system integrating domestically developed technologies has also been completed, which, through the identification of target molecules’ optical absorption spectra, is suitable for determining the relevant components of nutrient solutions. The SMWP developed by the consortium modularly integrates a microfluidic cuvette compatible with the system, an optical sensor, and signal processing electronics, which are based on the experience of the Microsystems Laboratory researchers gained in the development of microfluidic structures and infrared LED sources. The manufacturing technology for the polymer microfluidic cuvettes compatible with the optical measurement system was jointly developed by the domestic partners and the Dutch company Micronit B.V. (Enschede).

The Moore4Medical project was funded jointly by the Hungarian National Research, Development and Innovation Fund (2019-2.1.3-NEMZ_ECSEL-2020-00005) and the European Union (H2020-ECSEL-2019-IA-876190).